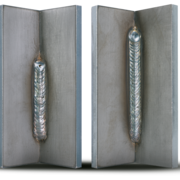

Low-spatter pulse welding.

The stable pulsed arc that can be controlled very well saves rework and time for other tasks. The pulsed process warrants low-spatter welding without any time-consuming rework across the entire synergy characteristic curve.

MicorBoost-technology for perfect welding results.

The innovative and patented Micorboost technology maximises power and the voltage reserve in the arc, optimising welding properties for all sheet metal as well as medium and heavy steel work. This results in outstanding welding results on steel, stainless steel, and aluminium.

EN1090 conformity + NFC technology.

Easily weld EN1090 compliantly thanks to the WPS booklet. Save some time- and cost-intensive individual tests of your welding results. The booklet contains independently certified welding instructions for all the relevant standard welding procedures. The MicorMIG series also keeps your parameter sets conveniently available via an NFC job card.

Future-proof by upgrade capacity.

Always just the functions you need: The NFC function makes the MicorMIG Pulse series welding units fully upgradeable, allowing you to subsequently install additional welding processes, welding programmes, and functions to facilitate work with NFC cards at any time, offline and without needing any external support.

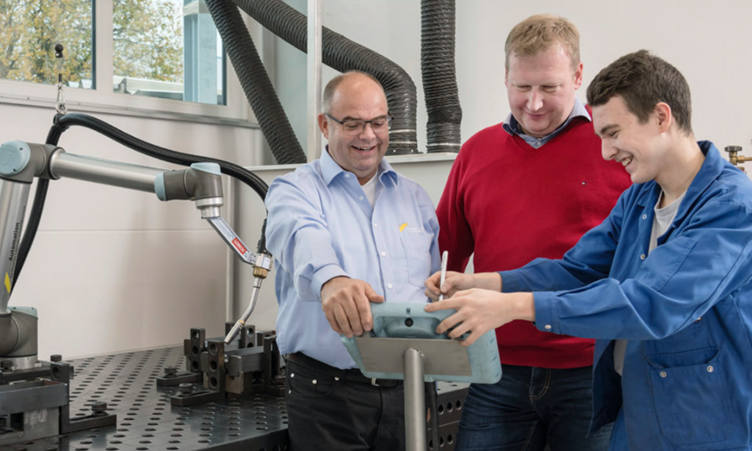

Perfect quality assurance with the authorisation concept.

NFC technology allows setting up of a personalised authorisation system for welding system operation. The MicorMIG allows use of NFC authorisation to ensure that only specific welders are allowed to adjust the corresponding parameters. A timed lock for the end of the working day additionally prevents unauthorised work on the device.

Outstanding price-performance ratio.

The MicorMIG Pulse offers an easy switch to a fully adjustable welding system. Profit from the optimal welding properties of the MicorMIG Pulse at an excellent price-performance ratio.

Energy efficiency by technology.

The Lorch MicorMIG Pulse combines robust performance with efficient inverter technology and a stand-by function. This reduces costs while achieving perfect welding results. Transformers are a thing of the past.