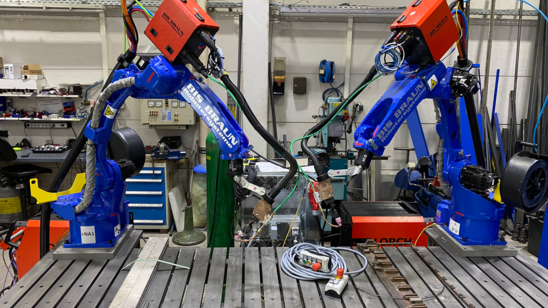

High-performance TIG.

Outstanding TIG technology and tried and tested inverter technology, protected in a robust industrial housing, optimise practicality and productivity in automated welding.

TIG cold wire with the RF05 CWT.

The optional RF-05 CWT robot feeder is compact, weight-optimised, powerful, and offers best insulation to ensure outstanding TIG quality for cold-wire welding as well as high speed with two different wire feed speed options.

Up to 100 welding tasks.

Complete recurring tasks quickly and efficiently! The Tiptronic job function saves and recalls the parameters for up to 100 welding tasks.

Perfect results in thin sheets.

The integrated pulse and fast pulse function at up to 20 kHz is particularly suitable for welding thin welding sheets. It permits outstanding weld pool control for perfect results even for difficult tasks.

Robust industrial housing.

The fully resilient industrial metal housing is extremely robust while its aerodynamic bulkhead keeps dust and dirt out of the system and makes it ideal for any outdoor use. The sturdy handles allow for suspension from a crane and can prevent potential tripping hazards by winding the welding cables. Combined with the double gas cylinder safety device, this warrants safety at all times.

Energy efficiency at full power.

The integrated stand-by function ensures turns individual components on and off automatically. The Thermocontrol sensors monitor system temperature and control the fan as required to save energy and reduce fan noise as well as the amount of dust entering the device.

Optimal parameters with the SmartBase.

Dank SmartBase-Technologie ist der Lichtbogen immer perfekt auf die ausgewählte Elektrode abgestimmt – Schweißparameter, Zündung und Arbeitsbereich werden automatisch ideal angepasst. Für optimale Freiheit kann die Feinjustierung des Lichtbogens individuell vorgenommen werden. Damit schweißen Sie garantiert mit einem optimalen Lichtbogen.